Control Biological Growth in Your Water Treatment System

Microbiological Control Inhibits Bacterial Growth in All Evaporative Heat Transfer Equipment

Microbiological Control Inhibits Bacterial Growth in All Evaporative Heat Transfer Equipment

The second biggest concern with your system after scale control is controlling the bacterial growth. Cooling towers are great breeding grounds for bacteria. Inside the tower is a warm, moist, sunlit environment in which bacteria of all sorts thrive. The inside of chillers also provides a great environment for other types of bacteria to grow.

These bacteria can produce a material that can act as an insulating slime barrier to reduce the efficiency of the chillers in much the same way that calcium carbonate (scale) creates a thick solid barrier. In addition, certain types of bacteria that thrive in the absence of oxygen, called anaerobic bacteria, can grow and produce acids as part of their metabolism that can attack the steel components of the chillers.

The Scale Free System regulates the time and release of copper-silver ions in the water. The Cu-Ag system has received recognition from the engineering community as well as the US EPA for biological treatment of domestic water supplies. This process is effective on Legionella, Pseudomonas, M. Avium, E. Coli, Salmonella and a host of other microbes as well.

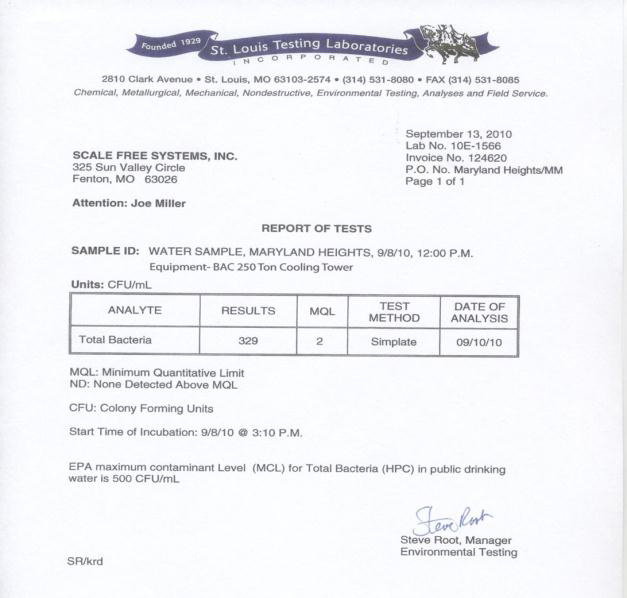

Just as we measure calcium minerals in parts per million, we measure quantities of bacteria in CFUs (Colony Forming Units) per milliliter, abbreviated CFU/ml. The higher the count is, the more bacteria you have. It is generally accepted that cooling tower water is only required to have less than 10,000 CFUs. Safe drinking water is required to have less than 500 CFUs. We had cooling tower water from a Scale Free System installation tested by an independent testing facility (St. Louis Testing Laboratories). The test results show SFS cooling tower water had 329 CFUs.